- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

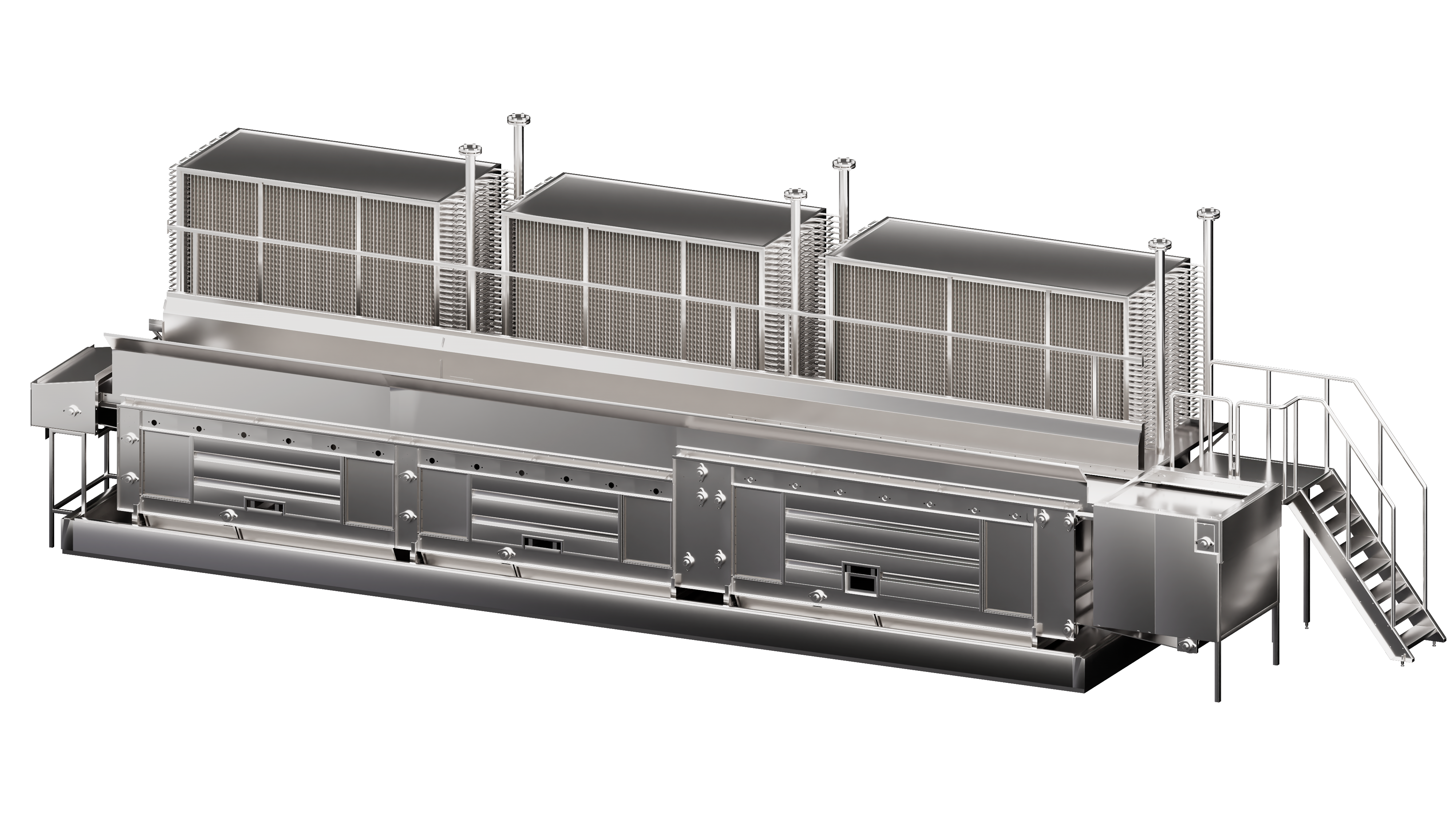

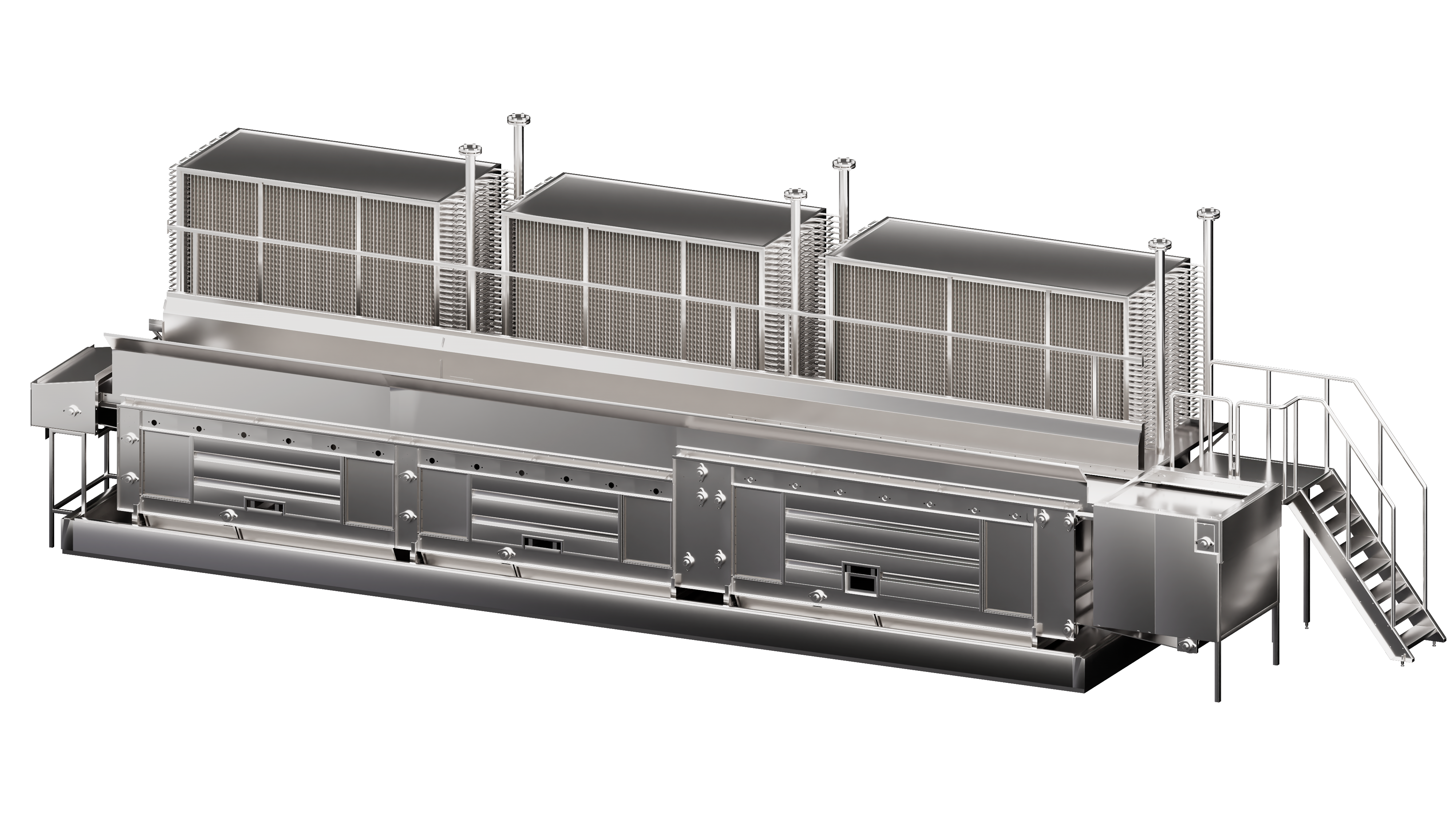

Fluidized bed freezer uses stainless steel mesh belt. During the transportation, the food is blown by a vertical upward high-speed, high-pressure air flow, and surrounded by lowtemperature air flow in a semi-suspended or suspended state, and then rapidly frozen. There is a mechanical vibration device with adjustable frequency under the belt to ensure that all kinds of products avoid adhesion when freezing.

The freezer uses two parts of conveyors. In the first part it quickly cools the food surface to freezing temperature. Under the action of the mechanical vibration device, the food particles do not stick together. In the second part the freezer deep freezes the food to guarantee the product freezing effect. The fluidized bed freezer is the best choice for freezing granular, flake, block, small piece of food and etc.

Features

1. The conveyor belt is a high-strength all stainless steel fluidized bed conveyor belt with small mesh pitch, which is suitable for frozen products of small products. The mesh belt is made of SUS304 stainless steel, which can ensure the hygienic requirements of the product.

2. The insulation enclosure body is wrapped with 0.7mm thick 304 stainless steel small corrugated compression reinforcement, the inner and outer packages are reinforced with 0.6mm 304 stainless steel concave convex compression reinforcement, and the inner PIR is filled with foam, with a total thickness of S = 150mm.

3. The whole bottom of the enclosure is made of 3mm thick stainless steel plate, with a slope of 1.4 °. The cleaning and frost flushing water will not leak, and the drainage is smooth and convenient.

4. The internal structural parts are made of 304 stainless steel, and the contact part with the conveyor belt is made of ultra-high molecular polyethylene antifriction material.

5. All aluminum (aluminum alloy) or 304 stainless steel tube evaporator, fin thickness is 0.4mm, corrosion resistance, good heat exchange and convenient cleaning.

6. The fan is an aluminum alloy centrifugal impeller with corrosion resistance, light weight and convenient cleaning.

7. The enclosure door is double-layer sealed and equipped with electric heater, which can be opened at any time without freezing and adhesion.

8. The conveyor belt is equipped with a water cleaning nozzle, which can be opened when in use to ensure food hygiene. 304 stainless steel high-pressure fan blows away water droplets to ensure that it will not affect the freezing of products.

9. The driving device adopts sew reducer with reliable performance.

10. The operation of mesh belt is controlled by variable frequency power supply, and the speed can be adjusted steplessly.

11. The front and rear sections of the mesh belt are equipped with frequency conversion vibration roller device to make the product not stick, and the mesh belt has good ventilation to ensure that the product is frozen and not stuck.

12. Stainless steel electric cabinet, digital display of temperature in the enclosure, and electrical components produced by Schneider Electric Company in France, with reliable performance.

Key features:

The evaporators are divided into 6 groups, and each group is equipped with damper device. During operation, the evaporator can be closed in sequence for hot gas defrosting, and can be defrosted and cleaned thoroughly after continuous use for one week (7 days).

Fluidized bed freezer uses stainless steel mesh belt. During the transportation, the food is blown by a vertical upward high-speed, high-pressure air flow, and surrounded by lowtemperature air flow in a semi-suspended or suspended state, and then rapidly frozen. There is a mechanical vibration device with adjustable frequency under the belt to ensure that all kinds of products avoid adhesion when freezing.

The freezer uses two parts of conveyors. In the first part it quickly cools the food surface to freezing temperature. Under the action of the mechanical vibration device, the food particles do not stick together. In the second part the freezer deep freezes the food to guarantee the product freezing effect. The fluidized bed freezer is the best choice for freezing granular, flake, block, small piece of food and etc.

Features

1. The conveyor belt is a high-strength all stainless steel fluidized bed conveyor belt with small mesh pitch, which is suitable for frozen products of small products. The mesh belt is made of SUS304 stainless steel, which can ensure the hygienic requirements of the product.

2. The insulation enclosure body is wrapped with 0.7mm thick 304 stainless steel small corrugated compression reinforcement, the inner and outer packages are reinforced with 0.6mm 304 stainless steel concave convex compression reinforcement, and the inner PIR is filled with foam, with a total thickness of S = 150mm.

3. The whole bottom of the enclosure is made of 3mm thick stainless steel plate, with a slope of 1.4 °. The cleaning and frost flushing water will not leak, and the drainage is smooth and convenient.

4. The internal structural parts are made of 304 stainless steel, and the contact part with the conveyor belt is made of ultra-high molecular polyethylene antifriction material.

5. All aluminum (aluminum alloy) or 304 stainless steel tube evaporator, fin thickness is 0.4mm, corrosion resistance, good heat exchange and convenient cleaning.

6. The fan is an aluminum alloy centrifugal impeller with corrosion resistance, light weight and convenient cleaning.

7. The enclosure door is double-layer sealed and equipped with electric heater, which can be opened at any time without freezing and adhesion.

8. The conveyor belt is equipped with a water cleaning nozzle, which can be opened when in use to ensure food hygiene. 304 stainless steel high-pressure fan blows away water droplets to ensure that it will not affect the freezing of products.

9. The driving device adopts sew reducer with reliable performance.

10. The operation of mesh belt is controlled by variable frequency power supply, and the speed can be adjusted steplessly.

11. The front and rear sections of the mesh belt are equipped with frequency conversion vibration roller device to make the product not stick, and the mesh belt has good ventilation to ensure that the product is frozen and not stuck.

12. Stainless steel electric cabinet, digital display of temperature in the enclosure, and electrical components produced by Schneider Electric Company in France, with reliable performance.

Key features:

The evaporators are divided into 6 groups, and each group is equipped with damper device. During operation, the evaporator can be closed in sequence for hot gas defrosting, and can be defrosted and cleaned thoroughly after continuous use for one week (7 days).