- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

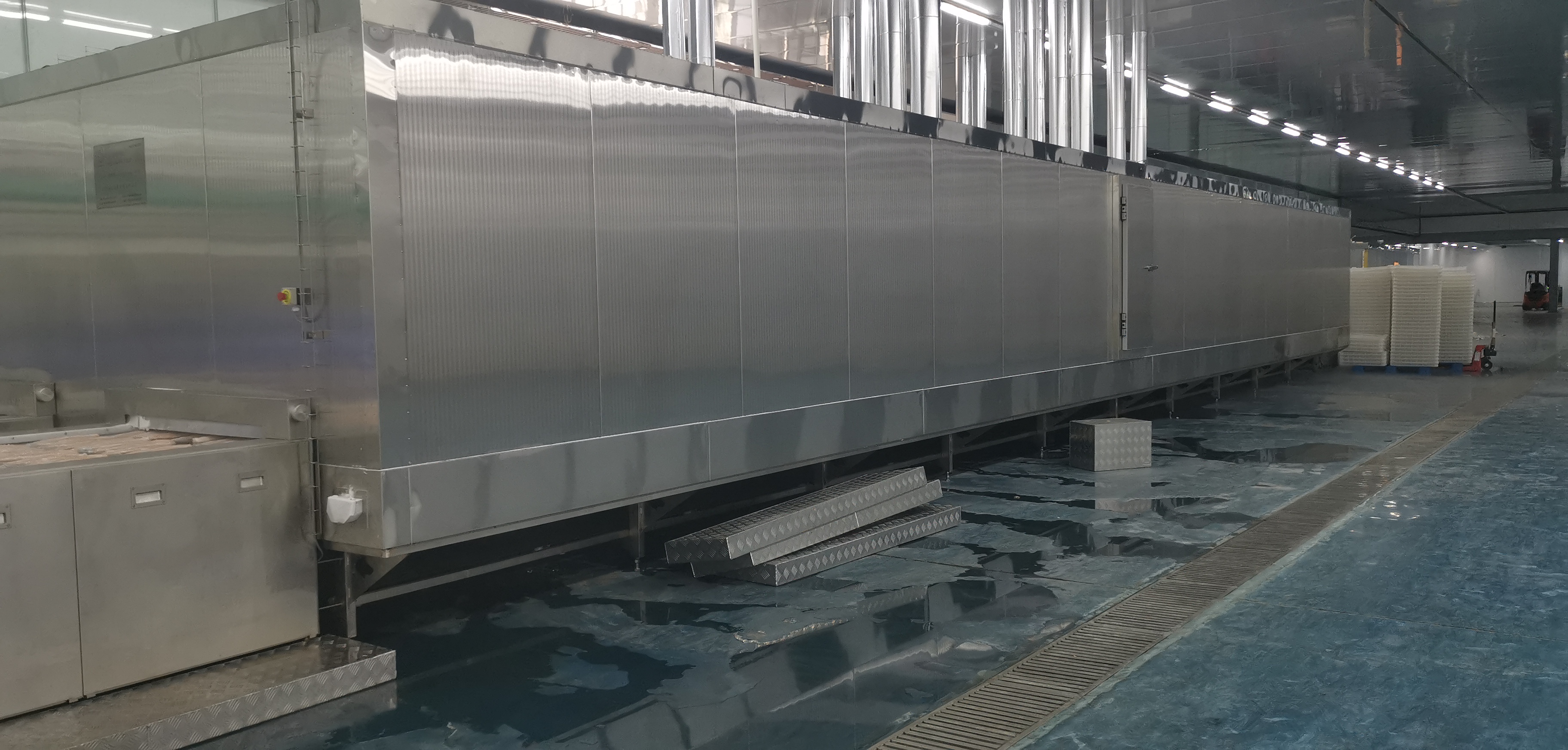

It is designed and manufactured in accordance with HACCP'S hygienic requirements for food processing equipment.

It is suitable for quickly freezing granular, diced, sliced food,including scallops, squid,shelled shrimp, fillet,etc. The food contacts the solid stainless-steel belt directly, which allows fast and efficient freezing.

Features:

Insulation part

The heat insulation cabinet is a high-density polyurethane insulation board with double- sided stainless steel, and the base plate is welded with a stainless-steel sink as a whole. Internal high pressure filling high pressure foaming machine for polyurethane foam injection, charge density is larger than 42kg/m3, base plate thickness S=120mm, the whole assembly of all connections are joint special rubber seal, to avoid the phenomenon of cold leakage equipment base body.

A reasonable maintenance access door for repair and maintenance is designed for freezing, adhesion and damage during the use of the sealing strip of the protective door, especially for the electrical heating device with safety voltage around the door frame. There is an anti-lock safety device on the inside of the access door.

Evaporator

1. The fin with the structure of the air flow, the tube shape high flanging, the plum flower arrangement tube hole, makes the evaporation efficiency better, cleaning more convenient and quicker.

2. With advanced tube expansion technology, the flanging and evaporating tube are tightly combined, and the heat transfer speed is faster.

3. The advanced way of donor side supply is used, and the fluid is throttle. The liquid supply is more uniform, the pumping and water thawing are more rapid, the heat transfer efficiency is high, and the cooling rate is fast.

4. The evaporator is out of the factory to carry out the pressure test of 24kg/cm3, and the drying nitrogen is pressed for 24 hours.

5. The ventilation system adopts centrifugal fan and completely closed low temperature moisture proof and waterproof motor. It has high efficiency, energy saving, low noise, smooth operation, fan blade for aluminum alloy impeller and all stainless-steel tube. It is sent back to the wind and flow, and the wind speed required for the quick freezing is reached with the smaller fan power.

6. The thick fin improves the cold and heat exchange path and regulates regular concave and convex patterns, which greatly improves the strength of the fins and is not easy to lodge. The density of the evaporating tube is large.

Conveyor belt

Strictly comply with the requirements of HACCP, designed and manufactured high- quality food grade SUS304 stainless steel conveyor belt to ensure food hygiene and safety. The surface is smooth and beautiful, and the service life is long.

Electrical control part

1. The electric control box is made of stainless steel.

2. The main components of the main electrical control are all used by Schneider or Siemens brand.

3. The operation of the solid belt is controlled by the frequency conversion power supply, and the speed of the solid belt can be adjusted stepless

4. The whole electrical control system is easy to operate and stable in operation.

5. The design of electrical circuit is mature, and the wiring is reasonable

6. Selection of famous brand electrical components, reliable performance

7. Reliable equipment operation fault detection display and alarm device

8. A safety loop is provided to ensure the safety of the operator.

9. Within the cabinet with dehumidification damp proof device to ensure the internal electrical components, drying, prolong the service life.

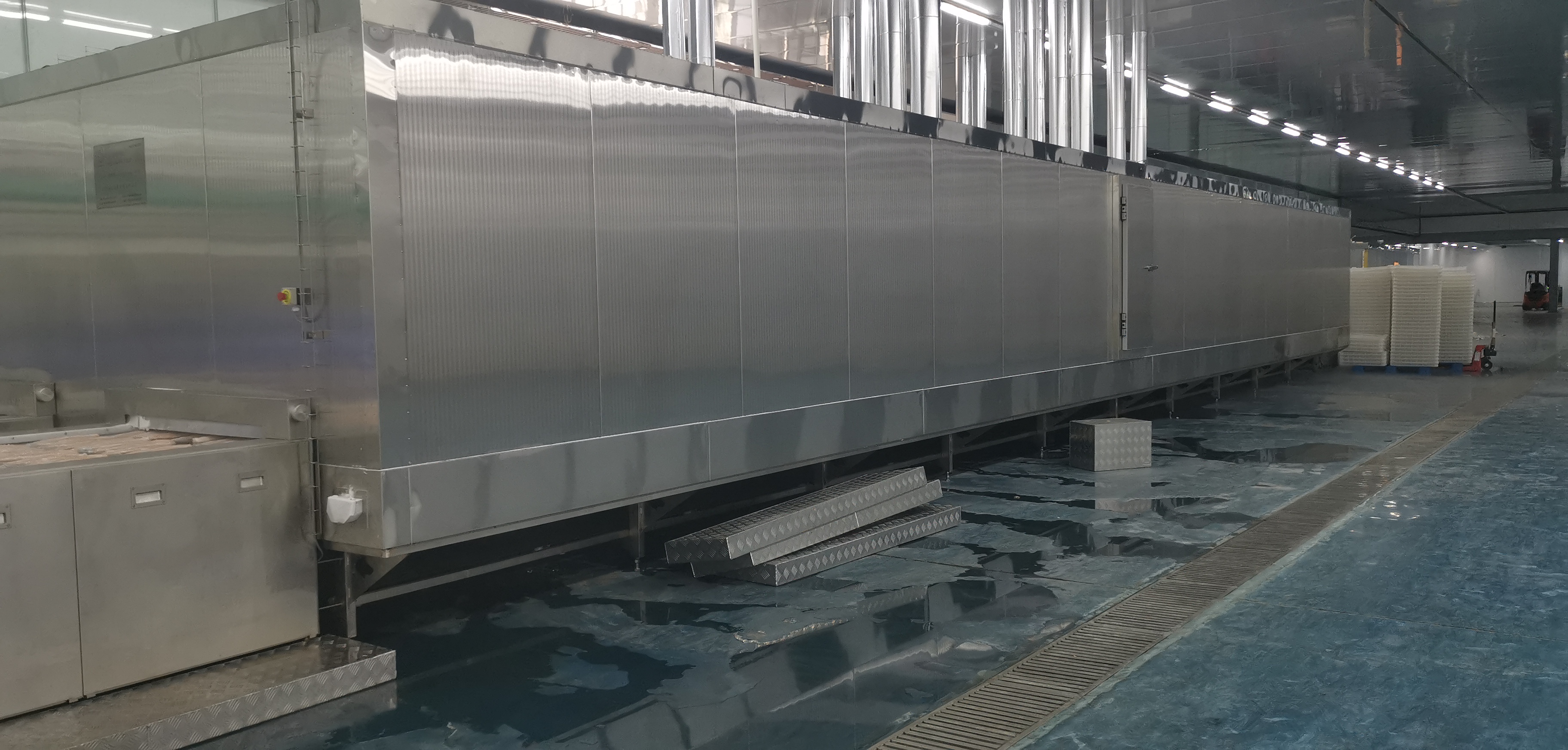

It is designed and manufactured in accordance with HACCP'S hygienic requirements for food processing equipment.

It is suitable for quickly freezing granular, diced, sliced food,including scallops, squid,shelled shrimp, fillet,etc. The food contacts the solid stainless-steel belt directly, which allows fast and efficient freezing.

Features:

Insulation part

The heat insulation cabinet is a high-density polyurethane insulation board with double- sided stainless steel, and the base plate is welded with a stainless-steel sink as a whole. Internal high pressure filling high pressure foaming machine for polyurethane foam injection, charge density is larger than 42kg/m3, base plate thickness S=120mm, the whole assembly of all connections are joint special rubber seal, to avoid the phenomenon of cold leakage equipment base body.

A reasonable maintenance access door for repair and maintenance is designed for freezing, adhesion and damage during the use of the sealing strip of the protective door, especially for the electrical heating device with safety voltage around the door frame. There is an anti-lock safety device on the inside of the access door.

Evaporator

1. The fin with the structure of the air flow, the tube shape high flanging, the plum flower arrangement tube hole, makes the evaporation efficiency better, cleaning more convenient and quicker.

2. With advanced tube expansion technology, the flanging and evaporating tube are tightly combined, and the heat transfer speed is faster.

3. The advanced way of donor side supply is used, and the fluid is throttle. The liquid supply is more uniform, the pumping and water thawing are more rapid, the heat transfer efficiency is high, and the cooling rate is fast.

4. The evaporator is out of the factory to carry out the pressure test of 24kg/cm3, and the drying nitrogen is pressed for 24 hours.

5. The ventilation system adopts centrifugal fan and completely closed low temperature moisture proof and waterproof motor. It has high efficiency, energy saving, low noise, smooth operation, fan blade for aluminum alloy impeller and all stainless-steel tube. It is sent back to the wind and flow, and the wind speed required for the quick freezing is reached with the smaller fan power.

6. The thick fin improves the cold and heat exchange path and regulates regular concave and convex patterns, which greatly improves the strength of the fins and is not easy to lodge. The density of the evaporating tube is large.

Conveyor belt

Strictly comply with the requirements of HACCP, designed and manufactured high- quality food grade SUS304 stainless steel conveyor belt to ensure food hygiene and safety. The surface is smooth and beautiful, and the service life is long.

Electrical control part

1. The electric control box is made of stainless steel.

2. The main components of the main electrical control are all used by Schneider or Siemens brand.

3. The operation of the solid belt is controlled by the frequency conversion power supply, and the speed of the solid belt can be adjusted stepless

4. The whole electrical control system is easy to operate and stable in operation.

5. The design of electrical circuit is mature, and the wiring is reasonable

6. Selection of famous brand electrical components, reliable performance

7. Reliable equipment operation fault detection display and alarm device

8. A safety loop is provided to ensure the safety of the operator.

9. Within the cabinet with dehumidification damp proof device to ensure the internal electrical components, drying, prolong the service life.